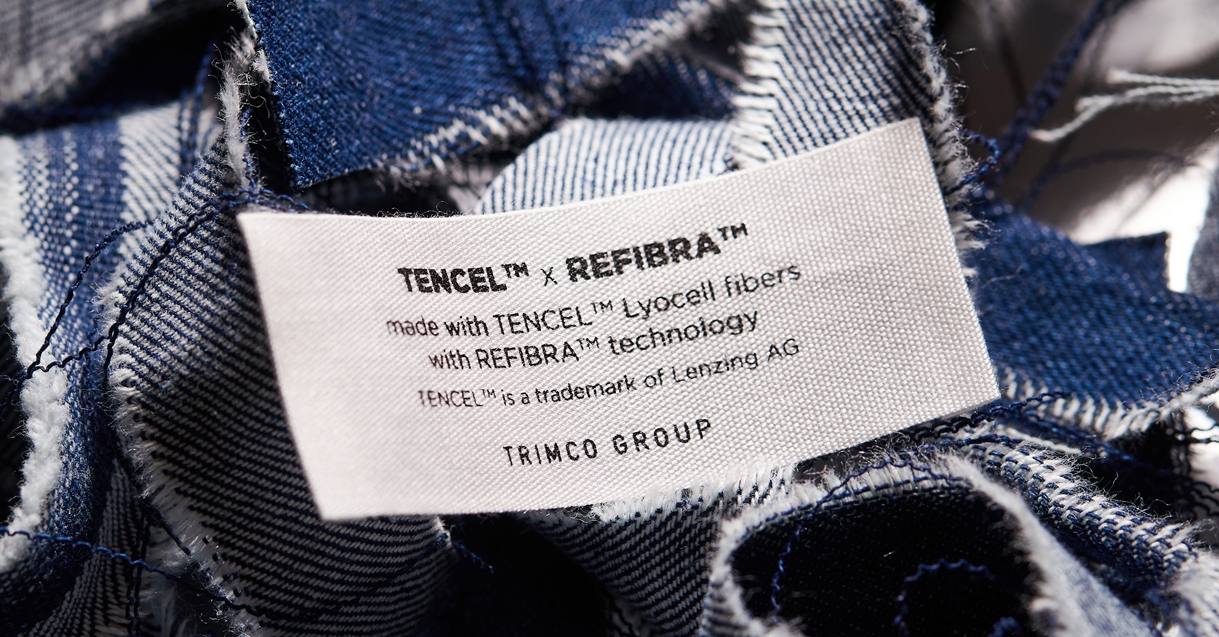

REFIBRA™ technology is a pioneering innovation in the realm of sustainable textiles. Developed by Lenzing AG, a global leader in wood-based cellulose fibers, REFIBRA™ represents a significant leap towards circular and eco-friendly fashion. The technology is centered around the use of wood pulp derived from sustainably managed forests and recycled cotton scraps.

Key Features of REFIBRA™ Technology:

- Wood Pulp Sourcing: REFIBRA™ fibers are predominantly crafted from wood pulp obtained from responsibly managed forests. This ensures a renewable and environmentally friendly source, reducing the industry’s dependence on traditional raw materials.

- Recycled Cotton: One of the standout features of REFIBRA™ is its utilization of recycled cotton scraps. By incorporating post-industrial cotton waste, the technology minimizes the environmental impact associated with cotton production, which is notorious for its water and pesticide usage.

- Closed-Loop Process: The production of REFIBRA™ fibers follows a closed-loop process, wherein the majority of the solvents and water used are recycled and reused. This significantly reduces the ecological footprint of the manufacturing process, making it more sustainable compared to traditional textile production methods.

- Reduced Carbon Footprint: REFIBRA™ technology contributes to lowering the carbon footprint of textiles by utilizing wood as a raw material. Wood, through photosynthesis, captures and stores carbon dioxide, making it an environmentally beneficial resource.

- High-Quality Fibers: Despite its eco-friendly focus, REFIBRA™ technology does not compromise on quality. The resulting fibers boast a soft and luxurious feel, making them suitable for a wide range of textile applications, from apparel to home textiles.

Environmental Impact and Benefits:

The adoption of REFIBRA™ technology brings forth a multitude of environmental benefits. By incorporating recycled materials and responsibly sourced wood pulp, this innovative approach contributes to:

- Conservation of Resources: Through the use of wood pulp and recycled cotton, REFIBRA™ reduces the strain on natural resources, promoting sustainability and responsible resource management.

- Waste Reduction: By utilizing cotton scraps that would otherwise end up as waste, REFIBRA™ minimizes the environmental impact associated with textile waste and contributes to a circular economy.

- Energy and Water Efficiency: The closed-loop process of REFIBRA™ production ensures efficient use of resources, minimizing energy consumption and water usage compared to conventional textile manufacturing methods.

REFIBRA™ technology stands at the forefront of sustainable innovation in the textile industry. Its commitment to using responsibly sourced materials and recycling cotton scraps demonstrates a paradigm shift towards more eco-friendly practices. As consumer demand for sustainable fashion continues to rise, technologies like REFIBRA™ pave the way for a greener and more sustainable future for the textile industry. By embracing such innovations, we can collectively contribute to a healthier planet while still enjoying the quality and comfort we expect from our textiles.